Rotary Platens and Belts

Rotary Platens and Belts

What is it?

If you are not familiar with rotary platens, there are a few different ways to use them.

The most popular use is for convex grinding. The chassis rotates on it’s spindle to allow you access for grinding on all 3 sides. Each side has a different span between the wheels for varying amounts of support (10, 8 or 6 inches). The longer the span, the less support the belt has, which results in a more convex grind. This is great for creating convex primary bevels or secondary bevels and sharpening.

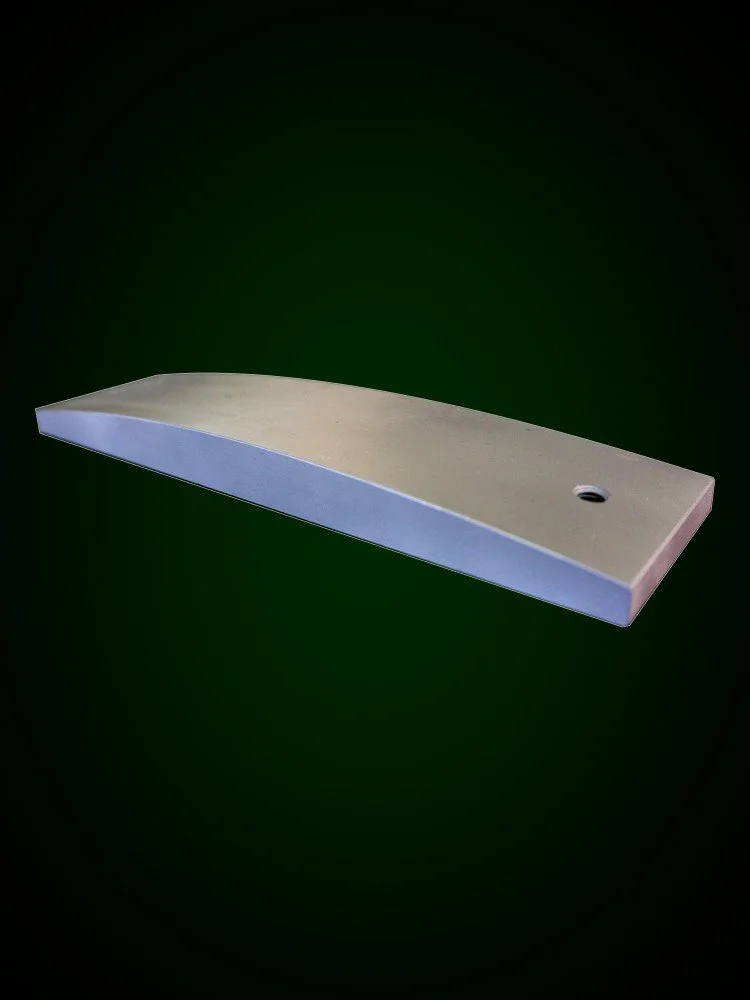

Another great use is for improved surface finish while flat grinding. If you use the steel platen behind the 10” span, you can achieve high polish finishes on your flat grinds because the rubber belt reduces belt joint bump. This should greatly reduce hand sanding time. WARNING: if you do not have a water or air chilled platen, we do not recommend doing large amounts of stock removal against the hard backer because there is a risk of overheating and melting your belt.

If you have another use for the rotary platen, please let us know so we can communicate that with anyone who is trying to learn.

What’s Included:

Complete Rotary Platen

Black Oxide Coated Steel Chassis (access holes for water or air lines to accommodate chilled platens. Water chilled platens sold separately)

3 grooved aluminum wheels with bearings and crush sleeves installed

3/4” Spindle Mount (If you buy a dedicated accessory arm for this attachment, there is no need to buy another spindle.)

Stainless Steel Pinch Point Guard

Rubber Belt (Part Number: 300J20) some pictures shown without belt for reference only. No separate belt purchase is necessary.

Case Hardened Steel Platen attached to chassis with 2 angle brackets (6.75” hole spacing on platen.)